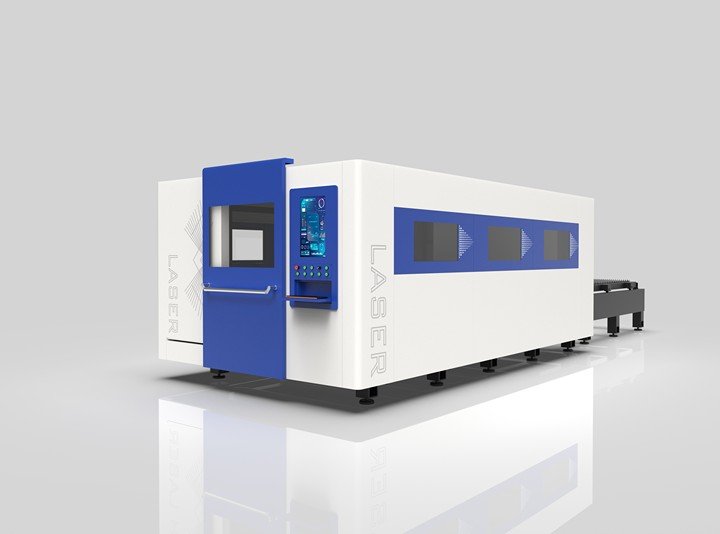

Laser welding has revolutionized the manufacturing industry with its precision, efficiency, and adaptability. However, like any advanced technology, laser welding can present challenges if not properly managed. In this article, we’ll explore common problems associated with laser welding and provide practical solutions to address them effectively. For manufacturers utilizing tools like the laser cutting machine, understanding and overcoming these challenges is essential to achieving optimal results.

I. The Most Common Issues in Laser Welding

A. Porosity in Welds

Porosity, or the formation of tiny holes in welds, is one of the most common issues faced in laser welding. It can compromise the structural integrity of the weld and lead to product defects. Porosity is often caused by:

– Contaminated surfaces

– Inadequate shielding gas

– Excessive heat input

Solution:

To minimize porosity, always clean the welding surfaces thoroughly to remove oil, dirt, and other contaminants. Use high-quality shielding gas and ensure proper gas flow. Additionally, adjusting the laser’s power settings can help control heat input to reduce porosity risks.

B. Cracking in Welds

Cracking occurs when the cooling process of the weld is too rapid, leading to high internal stress. This problem often arises when working with thick materials or dissimilar metals.

Solution:

Choose the appropriate filler material for the metals being welded. Optimize preheating and post-weld cooling processes to control temperature gradients and minimize stress. Equipment like a laser plate cutting machine can help create precise joints, reducing the likelihood of cracking.

C. Incomplete Fusion

Incomplete fusion refers to areas where the metals do not fully join together, resulting in weak welds. It is typically caused by:

– Insufficient laser power

– Incorrect welding speed

– Improper alignment

Solution:

Ensure proper alignment of the components being welded and increase the laser power if necessary. Adjust the welding speed to provide sufficient time for heat to penetrate the materials. Using tools like the best plate laser cutting machine can improve alignment accuracy, reducing the risk of incomplete fusion.

II. Key Factors to Consider When Troubleshooting Laser Welding

A. Material Properties

Different materials have varying thermal properties, reflectivity, and melting points. For instance, highly reflective materials like aluminum and copper may require adjustments to laser settings.

Solution:

Test the material’s response to the laser and make necessary adjustments. For tubular components, a Semi-Automatic Feeding Laser Tube Cutting Machine can ensure uniformity in materials, enhancing the overall welding process.

B. Laser Power and Beam Quality

The power and quality of the laser beam directly impact the success of the weld. Insufficient power can lead to weak welds, while excessive power can cause material distortion or burn-through.

Solution:

Regularly calibrate your laser equipment and select the appropriate power level for the material thickness and type. High-quality lasers ensure consistent beam delivery, reducing the likelihood of defects.

C. Shielding Gas

Shielding gas protects the weld pool from atmospheric contamination and contributes to the overall weld quality. Common shielding gases include argon, helium, and nitrogen, depending on the application.

Solution:

Choose the appropriate shielding gas based on the material being welded and adjust the flow rate to ensure complete coverage. Insufficient or excessive shielding gas flow can negatively impact weld quality.

III. Advanced Tools to Enhance Laser Welding Performance

Investing in advanced laser cutting and welding equipment can significantly improve results and reduce common problems. Modern tools like the laser plate cutting machine are designed to provide precise cuts, ensuring better joint alignment and weld quality. Similarly, the Semi-Automatic Feeding Laser Tube Cutting Machine can streamline the preparation process for tubular components, ensuring consistency and reducing manual errors.

When choosing the best plate laser cutting machine, consider factors such as cutting speed, precision, and automation features. These machines not only enhance welding performance but also optimize productivity, making them an excellent choice for manufacturers looking to stay ahead in the competitive market.

IV. Practical Tips for Successful Laser Welding

1. Thoroughly Prepare Materials

Proper cleaning and preparation of materials are crucial to achieving high-quality welds. Remove contaminants and ensure the edges are properly aligned before welding.

2. Optimize Laser Settings

Experiment with laser power, speed, and focus to identify the optimal settings for your specific application. Conduct trial welds on scrap materials to fine-tune parameters.

3. Monitor Weld Quality

Regularly inspect welds for defects and make necessary adjustments to the welding process. Non-destructive testing methods can help identify internal defects without damaging the product.

4. Train Operators

Ensure that operators are trained in handling laser welding equipment and understand the key factors influencing weld quality. Skilled operators can troubleshoot problems quickly and efficiently.

V. Conclusion

Laser welding offers unparalleled precision and efficiency, but addressing common challenges is essential to unlocking its full potential. By understanding issues like porosity, cracking, and incomplete fusion, and investing in advanced equipment like the best plate laser cutting machine and the Semi-Automatic Feeding Laser Tube Cutting Machine, manufacturers can significantly improve their welding outcomes. Regular maintenance, proper training, and a proactive approach to troubleshooting will ensure consistent performance and high-quality results in all laser welding applications.

The laser cutting machine is at the core of modern manufacturing, and by optimizing its use, businesses can remain competitive while delivering exceptional products.